What is a DWS System?

Dimensioning, Weighing, and Scanning (DWS) Systems are a type of warehouse and manufacturing automation solution designed to boost operational throughput, that is, the number of items processed within a set period. As its name indicates, the supply chain automation system assists in automatically capturing three key details of a shipment, object, or parcel:

- Dimensions (L x B x H),

- Dead weight

- Data encrypted on the object’s label

The captured details prove to be integral for operations with extensive logistics and intralogistics involved in the workflow, including automated warehouse systems suites such as those in e-commerce and 3PL (third-party logistics) company warehouses, as well as production units.

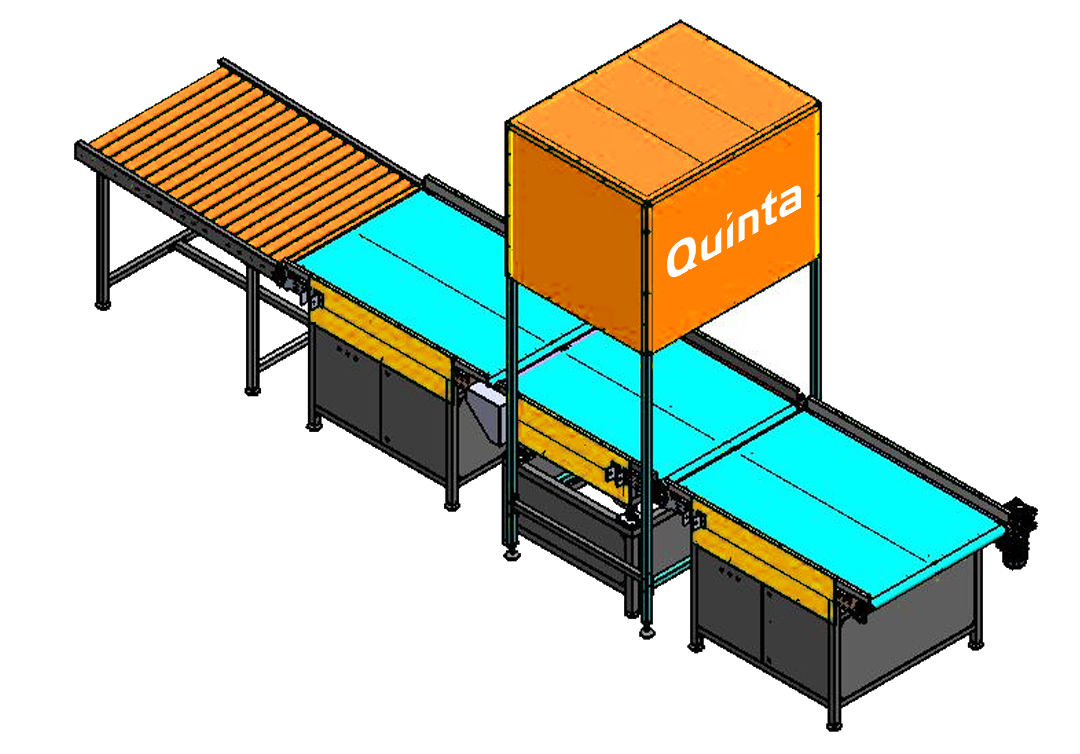

Parcel size and weight measurement simplified with one of the best DWS systems for warehouses in the market:

What is the Purpose of a DWS System?

In an end-to-end or semi-automated warehouse or any other intralogistics workflow, DWS Systems serve as the first or one of the first automation touchpoints, acting as an enabler of intelligent decision-making. Automating volumetric weight calculation, the solution supports the following warehouse and manufacturing automation use cases:

Volumetric Weight-Based Billing

Carrier charges or transportation costs depend as much on the space occupied by shipments as on their dead weight. This approach to billing is based on the following considerations:

- Suboptimal Use of Transportation Load Capacity: Extra-large shipments, with relatively light dead weight, cause space shortage for other parcels in the batch. As the number of freight shipments increases, the vehicle fleet must undertake extra trips, thereby incurring increased fuel charges without maximising the load capacity of the vehicles.

- Unused Freight Volume: Given that vehicles have fixed load capacity for optimal mileage, as well as safe and unhindered journeys, overloading them is not an option. Hence, when excessively heavy yet compact shipments are part of a freight, the optimal volume of the carrier is unutilised.

Volumetric weight-based billing ensures optimised shipping charges, based on both dimensions and dead weight. This billing process helps prevent overcharging or undercharging for any type of shipment, ensuring transparency.

Intelligent Sortation, Storage, & Retrieval

At the sortation workstation, also known as the sorter, shipments are segregated based on PIN Codes encrypted on their labels, thus paving the way for optimised and automated picking. Informed by the shipment’s dead weight, the specialised warehouse robots, commanded by the WMS (Warehouse Management System) to carry shipments for the next workflow, pick the total number of shipments based on their load capacity.

WMS Systems, the driver of decision-making in warehouses, also designate robots according to the shipment volume and the carrier size of the transportation robot.

The same principle is used to optimise racks and shelves, covering the horizontal and vertical space of the storage unit while also keeping in mind the outbound date, ease of retrieval, etc.

Breaking Down DWS: What Are the Key Components of the Solution?

DWS systems comprises three key components that enable instant as well as automatic dimensioning, weighing, and label reading:

3D Profilers/Dimensioners in DWS Solutions

Leveraging a variety of Machine Vision technologies, dimensioners help determine precise L x B x H measurements of shipments, regardless of their form—cuboidal, non-cuboidal, or irregular-shaped.

Scales or Weighing System, DWS Solutions have

DWS solutions come with a variety of integrated volumetric weight measurement systems. Among the three popular automatic weighing scales used industrially, warehouses generally use strain gauge load cell scales, which are not only rugged but also suitable for moving as well as static parcels/ objects. Moreover, these scales have massive load capacities and, therefore, can weigh large pallets.

Code Readers in Parcel Dimensioning Systems

Based on the types of labels frequently found on the warehouse shipments or the manufacturing product being shipped, the DWS System may include a label decryption device, capable of reading barcodes, QR codes, laser-embossed codes, alphanumeric codes, etc., as applicable. Depending on the read rate of the device in question, it can also decode a moving parcel.

What Are the Different Types of DWS Systems Used for Volumetric Weight Measurement?

In terms of configuration, DWS Systems can be categorised in two ways. Static vs Dynamic Dimensioning and Weighing Systems, which prove to be the best DWS systems for warehouses, logistics, and supply chain management?

Static DWS Systems

Designed to auto-capture L x B x H, dead weight, and label-encrypted information of static shipments, Static DWS are commonly characterised by their compact form factor. Moreover, another marker of a Static DWS solution is that the infeed shipments are generally manually handled to capture their different dimensions.

Generally, after a Static DWS System processes a shipment, it is carried to the next Warehouse Automation workflow, with the help of robots.

Dynamic DWS Systems

Dynamic DWS Systems are built for auto-dimensioning shipments on the move. Hence, they require a conveyor belt for carrying shipments from the starting point of the infeed to the range of vision of the dimensioners and code readers. To ensure manual-intervention-free dimensioning, Dynamic DWS have multiple 3D profilers, strategically placed at different angles to capture every dimension at a go. While for cuboidal parcels, a single dimensioner suffices, for complex and irregular shapes, a configuration of multiple dimensioners is used.

Ideal for building a seamlessly connected workflow, the DWS conveyor belt extends into other workflows, particularly into the sorter, for segregating shipments based on their destination.

Integrate automated parcel dimensioning with dynamic parcel scanning solutions and weighing scales:

How Does a DWS System Work?

A Step-By-Step Workflow Highlighting the Importance of Automation in Logistics and Supply Chain Management

Package Enters the System

A parcel is placed on the automatic dimensioning and weighing machine—on the in-feed conveyor of dynamic systems, or on the platform of static systems

Dimensioning

3D cameras or laser sensors capture the length, width, and height of the package.

Weighing

The package is simultaneously weighed using an integrated scale.

Barcode Scanning

High-speed barcode scanners read 1D or 2D codes from multiple package sides. The system identifies the package and associates it with the correct shipment/order.

Billing

Accurate L x B x H measurements are used to calculate volumetric weight, which is taken into consideration, along with the dead weight and the distance the package is set to travel, for determining shipping charges.

Data Integration

The collected data (dimensions, weight, barcode ID) is sent to the Warehouse Management System (WMS), ERP, or labelling software. Real-time synchronisation ensures accuracy for billing, routing, and inventory tracking.

Sorting or Labelling

Based on the data, the supply chain automation solution may trigger automatic labelling, sorting, or routing for further processing.

What Are Scenarios Where DWS Systems Are Commonly Used?

The supply chain automation solution is usually found in:

- In-House E-Commerce Warehouses

- 3PL Company Warehouses

- Postal and Courier Companies

What Are the Key Benefits of DWS Systems?

The advantages of implementing a robust DWS System, particularly for supply chain automation, are:

Improved Billing Accuracy &Transparency

Improving the accuracy of the dimensional measurements, operations managers can better justify their logistics charges, thanks to the concrete data.

In this manner, the company can prevent reputation damage and poor customer experience due to unintentional overcharging. Similarly, the more accurate the dimensions, and thus the volumetric weight, the less likely it is for the company to suffer revenue leakage due to undercharging.

Further, compared to peers who have yet to automate dimensioning, companies implementing DWS Solutions can offer industry-best rates by better planning their operations and optimising their operations, including packing, logistics planning, etc.

Greater Throughput & Solution-to-Solution Coordination

DWS Systems do far more than save manual labour and the time it consumes during dimensioning, weighing, and scanning. The data the solution auto-captures is the foundation of automation across the warehouses because, based on the input gathered from the DWS setup, the WMS software optimises the subsequent steps of the workflow, while enabling—at the same time—the WCS to harmonise the use of other autonomous or automated solutions involved in the warehouse management processes.

Increased Profitability

The higher the throughput, the more inventory cycles the operations can potentially process, thus enabling the warehouse to drastically increase revenue.

Stronger Process Management Capabilities & Easier Scalability

DWS Systems set the groundwork for further automation, allowing operations managers to track as well as control workflows in real-time.

What is the implementation cost of the best DWS Systems for warehouses?

The best avatars of the solution are customised. However, our efforts remain focused on efficacy, resilience, and cost-effectiveness.

Why Quinta DWS?

Quinta features among the top industrial automation companies in India.

Our Dimensioning, Weighing and Scanning (DWS) system is ideal for the logistics and 3PL companies that want to accurately measure the actual weight and volumetric weight of the shipments, whether they are plastic polybags, cartons, parcels, or uneven-sized items, among others.

Quinta’s Track Record of DWS Solution Installation

Quinta features among the top industrial automation companies in India.

Our Dimensioning, Weighing and Scanning (DWS) system is ideal for the logistics and 3PL companies that want to accurately measure the actual weight and volumetric weight of the shipments, whether they are plastic polybags, cartons, parcels, or uneven-sized items, among others.

Embrace parcel volume measurements for billing accuracy with Quinta’s logistics parcel dimensioning, weighing, scanning systems and WMS (Warehouse Management System) software:

The Impact of DWS Installations Done by Quinta—

A Glimpse of the Difference Our Supply Chain Automation Solutions Make

High Throughput

Never-seen-before operational efficiency

Shipment Variety

Different package types processed, —polybags, boxes, irregular parcels—across a wide range of shapes and sizes, with very few or zero no-reads

Billing Accuracy

Risk of undercharging and overcharging is mitigated

Rapid Deployment

Swift implementation followed by minimal downtime

Specifications of the Quinta DWS Systems

Here are some salient points about Quinta’s DWS Systems, demonstrating the impact we want to make as one of the leading warehouse automation companies in India:

- LBH—Max 1200 x 1000 x 1000; Min 100 x 100 x 100

- Weight—Max 80 kg; Min 500 g

- Types of Packages—Flyers, Carton Boxes, Shrink-Wrapped Boxes, Poly-Wrapped Boxes, and Non-cuboidal Shipments (Even Irregular-Shaped Items)

Frequently Asked Question

D= Dimensioning

W= Weighing

S= Scanning

A DWS (Dimensioning, Weighing, and Scanning) system is an integrated solution that automatically captures a package’s dimensions, weight, and barcode data to streamline logistics, improve accuracy, and ensure proper billing and routing.

DWS systems are widely used in:

- Courier and Express Parcel (CEP) services

- Warehouses and distribution centres

- E-commerce fulfilment centres

- Freight forwarding and logistics hubs

- Retail and supply chain operations

A standard DWS machine includes:

- 3D dimensioning sensors or cameras

- Weighing scale (static or dynamic)

- Barcode scanner (1D/2D)

- Software interface for integration and analytics

Yes. Most DWS systems are designed to measure irregular, non-cubic, and soft packages accurately using advanced 3D sensors and volumetric algorithms.

Static DWS: Manual or semi-automated. The package is placed on a stationary platform.

Dynamic DWS: Fully automated with conveyor belts that process packages in motion—ideal for high-volume operations.

Example: Automated Parcel Sorting, Parcel Dimensioning

Dimensioning, weighing and scanning systems improve:

- Billing accuracy (avoids revenue loss)

- Operational speed (fewer manual processes)

- Error reduction (fewer returns and misroutes)

- This leads to significant cost savings and better ROI.

Yes. Leading DWS sortation solutions, including Quinta’s, offer API-based or plug-and-play integration with most ERP, WMS, and shipping platforms.

DWS Automation requires minimal maintenance. Regular checks include:

- Cleaning sensors and scales

- Software updates

- Calibration (based on usage)

- Support is often available via remote diagnostics, service contracts, or on-site technicians