Quinta DWS

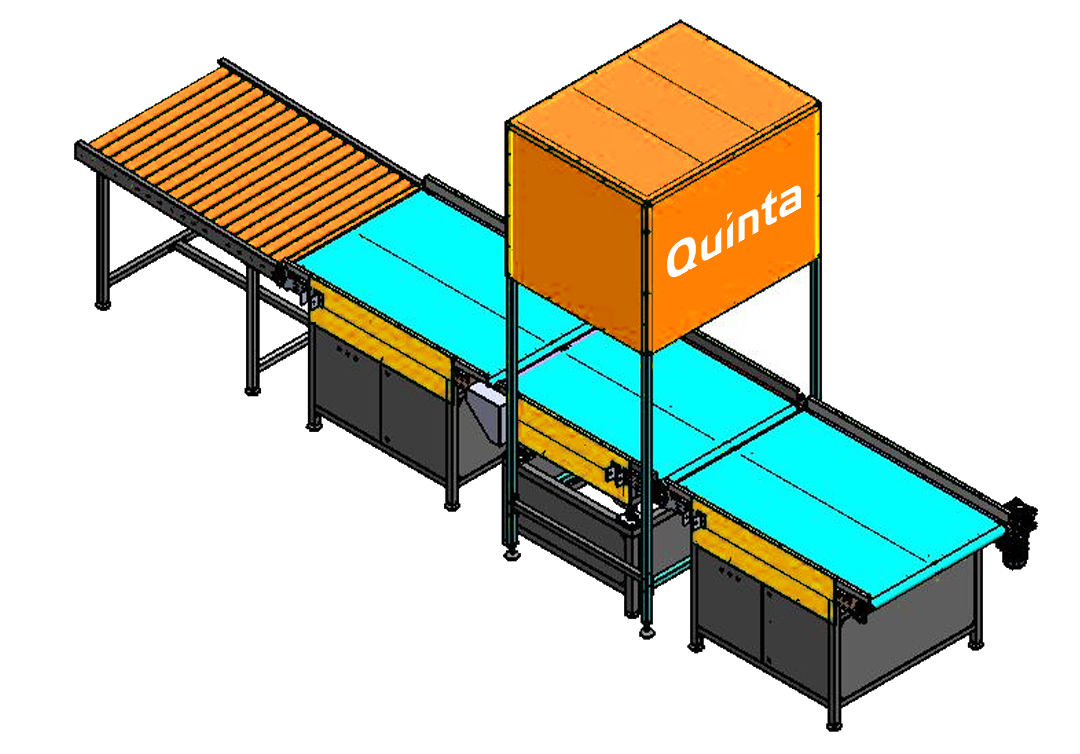

Quinta’s Dynamic Dimensioning, Weighing and Scanning (DWS) system is a robust solution ideal for the logistics and 3PL companies who want to accurately measure the actual weight and volumetric weight of the shipments whether they are plastic polybags, cartons, parcels, uneven size items among others.

Why Quinta DWS

1. Right Profilers and Cameras for specific use cases

The profilers and cameras form the core of DWS system. Quinta, with its expertise of working with several technology partners, would pick the right 3D profiler system for capturing the length, breadth and height data and the camera system for ensuring accurate scanning of the shipments.

2. Robust WCS

For reaping the full benefits of the DWS system, WCS layer plays a key role. Quinta’s expertise of integrating with hardware technology on one hand and WMS systems on the other, in a flexible and seamless way makes the life easy for Quinta’s customers.

3. Overall durability of the system

Besides the technology, the control, mechanical and electrical systems in the DWS play a very crucial role in the longevity of the system itself. Every component selected in the DWS is done keeping in mind the right components required for the longevity.

4. Support

For reaping the full benefits of the DWS system, WCS layer plays a key role. Quinta’s expertise of integrating with hardware technology on one hand and WMS systems on the other, in a flexible and seamless way makes the life easy for Quinta’s customers.

Case Studies

Quinta implemented the conveyor based DWS Systems across the warehouse of a large 3PL provider in India. The customer struggled with the below

- slower manual DWS system whose throughput was lower

- billing to their customers was not accurate affecting their revenues

- integration with their ERP system was not stable that resulted in customer experience getting affected

Quinta’s DWS system was implemented, and the below results were seen:

High throughput demands: With e-commerce growth, the facility had to process very high shipment volumes per hour without slowing down.

Varied shipments: Packages came in all sizes and shapes (polybags, boxes, irregular parcels), making manual handling slow and error prone.

Billing accuracy: Inaccurate weight capture risked undercharging or overcharging customers. The client needed precise data to optimize freight charges and recover all payable revenue.

Rapid deployment: The solution had to be implemented quickly to meet customer commitments with minimal downtime.

How DWS Systems Work

A DWS system is an integrated solution designed to automate and streamline package handling in logistics, warehousing, and e-commerce fulfilment. It combines dimensioning, weighing, and barcode scanning into one efficient process.

Step-by-Step Workflow:

- Package Enters the System

A parcel is placed on a conveyor (for dynamic systems) or a platform (for static systems).

The system is triggered automatically or by a user.

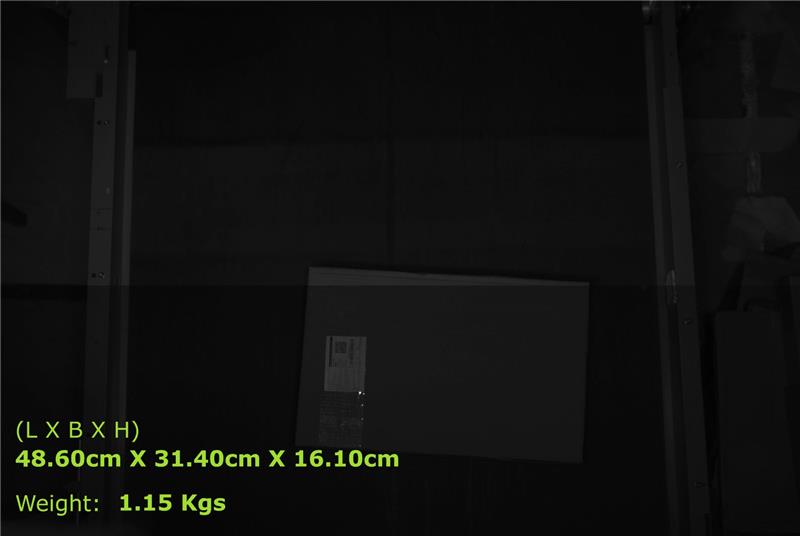

- Dimensioning

3D cameras or laser sensors capture the length, width, and height of the package.

Accurate measurements are used to calculate volumetric weight.

- Weighing

The package is simultaneously weighed using an integrated scale.

The actual gross weight is compared with the volumetric weight to determine shipping charges.

- Barcode Scanning

High-speed barcode scanners read 1D or 2D codes from multiple package sides.

The system identifies the package and associates it with the correct shipment/order.

- Data Integration

The collected data (dimensions, weight, barcode ID) is sent to the Warehouse Management System (WMS), ERP, or labelling software.

Real-time synchronization ensures accuracy for billing, routing, and inventory tracking.

- Sorting or Labelling

Based on the data, the system may trigger automatic labelling, sorting, or routing for further processing.

Use cases of DWS

Inbound

DWS in inbound of 3PL is used for capturing the right dimensions that can help raise a bill to the customers of 3PL.

Sorting

DWS can drive help sort the parcels or shipments based on the weight or size or shipment destinations into various bins and improve sortation accuracy.

Storage

In case of large shipments, storage location can be triggered by the DWS system output where the shipment and bin locations are mapped.

Billing

DWS system can trigger the bill to the customers based on the volumetric weight of the shipments.

Sortation

Sorting the parcels based on the size and weight is crucial for courier companies and accurate billing

Higher throughput and tracking

Enable quicker processing for maintaining throughput SLA with its customers. Also for enabling visibility to the customers regarding the shipment location.

Specifications of the Quinta DWS System

- Throughput: Upto 1500 PPH

- LBH max of 1200 x 1000 x 1000, min of 100 x 100 x 100

- Weight max of 80 kg to 500 gms

- Types of Packages: Flyers, Carton Boxes, Shrink wrapped boxes, poly wrapped boxes,

- other non-cuboidal items

Features of Profiler System from Quinta

Manual Mode of operation

In case of no read from the system, Quinta DWS provides an option to manually scan the shipments and associate to dimensions

WCS Easy integration

Quinta WCS is easily integrable with any ERP/WMS for a seamless data exchange.

Frequently Asked Question

A DWS (Dimensioning, Weighing, and Scanning) system is an integrated solution that automatically captures a package’s dimensions, weight, and barcode data to streamline logistics, improve accuracy, and ensure proper billing and routing.

DWS systems are widely used in:

- Courier and Express Parcel (CEP) services

- Warehouses and distribution centers

- E-commerce fulfillment centers

- Freight forwarding and logistics hubs

- Retail and supply chain operations

A standard DWS machine includes:

- 3D dimensioning sensors or cameras

- Weighing scale (static or dynamic)

- Barcode scanner (1D/2D)

- Software interface for integration and analytics

Yes. Most DWS systems are designed to measure irregular, non-cubic, and soft packages accurately using advanced 3D sensors and volumetric algorithms.

Static DWS: Manual or semi-automated. The package is placed on a stationary platform.

Dynamic DWS: Fully automated with conveyor belts that process packages in motion—ideal for high-volume operations.

Example: Automated Parcel Sorting, Parcel Dimensioning

Dimensioning Weighing Scanning System improve:

- Billing accuracy (avoids revenue loss)

- Operational speed (fewer manual processes)

- Error reduction (fewer returns and misroutes)

This leads to significant cost savings and better ROI.

Yes. Leading DWS Sortation solutions, including Quinta’s, offer API-based or plug-and-play integration with most ERP, WMS, and shipping platforms.

DWS Automation require minimal maintenance. Regular checks include:

- Cleaning sensors and scales

- Software updates

- Calibration (based on usage)

- Support is often available via remote diagnostics, service contracts, or on-site technicians.