Laser Marking

- Home

- Our Products

- Laser Marking

What Are Laser Markers?

Traceability is a top priority in dynamic warehousing, manufacturing, and other industrial environments where assets and their labels undergo constant wear and tear.

To ensure permanent, damage-proof labelling, lasers are used to etch, engrave, or mark surfaces. Here’s why laser marking machines are used in heavy-duty operations:

- Improved Productivity: Less time spent on labelling assets

- Uninterrupted Workflow: No-reads caused by damaged or faded labels eliminated

- Smooth Asset Management: Quick asset tracking enabled by permanent labels

Why Embrace Laser Marking Equipment Over Other Labelling Solutions?

Industries where laser marking machines are crucial:

Unlike print-and-stick labels, robust laser markers support permanent labelling in demanding sectors, such as manufacturing and intralogistics, where surfaces are exposed to erosion and damage caused by harsh industrial conditions. As a full-stack warehouse automation provider, Quinta has integrated laser marking machines across various facilities, helping manufacturers and logistics companies in asset identification and asset tracking, among other key tasks, depending on the workflow.

The different surfaces that laser marking machines help label:

Laser markers, unlike other labelling and permanent marking solutions, are defined by their versatility. The marking device is compatible with metals, resins, thermoplastics, silicon, glass, and ceramics, among other surfaces, including that of equipment, freight, pallets, bins, shipments, and fleets—in-warehouse and delivery vehicles like mobile robots, forklifts, carriers, and trucks.

The various label types generated by label marking systems:

Laser markers are used to effortlessly create part markings, barcodes, and QR codes.

Laser Marking Software

How Label Marking Machines Ensure Desired Label Shapes and Fine Design

The contrast, texture, and precision of the labels are determined by the label marking software, which is the user interface for controlling the focus position, marking speed, power and pulse frequency of the laser beams. These settings are key for optimising the readability and the resilience of the markings.

The Edge of Laser-Embossed Precision Marking

Long-Lasting Labels

Improved Readability

High-Contrast Marking

Permanent Non-Tactile Labels

High-Throughput Compatibility

What are the Different Types of Laser Marking Machines?

- Fibre Laser Marker: Swift, high-contrast laser marking machine for deep engraving on metals and plastics

- CO2 Laser Marker: Infrared laser marking system used to mark non-metals, including plastics, wood, glass, and paper

- Solid-State Laser Marker: Laser marking equipment for precision marking on metals, ceramics, and certain plastics

Why Quinta’s Laser Marking Systems?

We help businesses adopt and install laser markers with specifications that comprehensively meet their use cases across operations. Moreover, the real value addition of Quinta’s team of experts while implementing laser markers is setting up an efficient asset tracking and management mechanism.

Quinta experts endeavour to seamlessly integrate robust laser markers in your Manufacturing Execution System (MES) or ERP software.

Use Cases of Quinta’s Laser Marking Systems

Direct Part Marking

Use laser markers installed and integrated by Quinta to etch equipment, medical, industrial, or consumer goods, and automobile parts in your manufacturing unit.

Swift Format Changeover

Want to change the laser’s intensity and label type, tactile or non-tactile, depending on the surface and object? Laser marking machines adopted under Quinta’s value-added services are quick to react, enabling adaptable production lines.

Diverse Label Types

Laser markers Quinta helps implement into your workflow can engrave, etch, or mark permanent OEM logos, barcodes, alphanumeric text, QR codes, quality certification marks, and other code types. The labels are not just used in manufacturing units but also in warehouses or intralogistics for asset tracking, which is the core of Warehouse Automation.

Impact of Laser Marking Machines

- Crisp Labels: High-resolution, high-contrast labels for industry-specific labelling, including targeted paint-coat removal

- Better Readability: Fewer no-reads compared to dot-pin or acid etching marking processes for uninterrupted, optimal throughput

- Improved Safety in the Labelling Process: Safer than other marking processes, such as dot-pin or acid etching

- Increase Ease of Use: No-contact, targeted marking without expensive clamping or fixtures, thanks to the laser marking software adjusting the laser’s intensity as per the surface

- Mess-Free Labelling Process: No spills, abrasion, or damage on the surrounding components

- Reduced Cost of Ownership: No consumables for operating the device, reduced electrical consumption, and damage-proof labels requiring zero replacement cost

- Environmentally Friendly: No use of chemicals, inks, or solvents

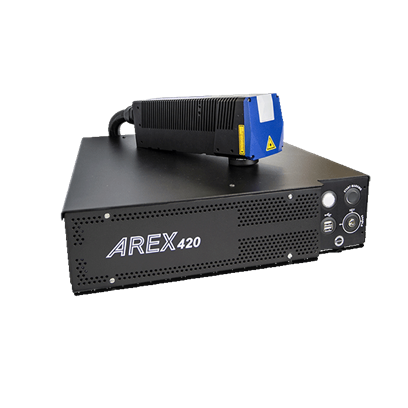

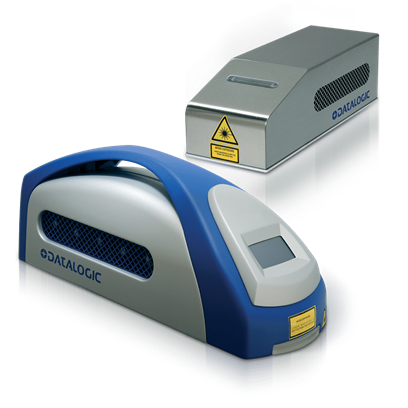

Products

Frequently Asked Questions

Laser marking machines focus a powerful light beam on a surface to create a label or part marking on a surface.

Laser marking systems create permanent and tamper-proof labels, including barcodes, QR codes, part markings, etc., thus ensuring effortless, error-free, and real-time asset tracking with minimal downtime due to MES- and ERP-integration.

Here is a list of materials on which various types of laser marking systems can be used to successfully create labels/markings:

- Metals

- Plastics

- Resins

- Ceramics

- Glass

- Wood

The list is not exhaustive.

The main types of laser marking systems are:

- Fibre laser markers for metals and plastics

- CO2 laser markers for non-metals

- Solid-state laser markers for precision marking on metals, ceramics, types of plastics, and a diverse set of materials

The markings are engraved instantly and usually last permanently, unless the object itself begins to corrode.

Selecting the laser marking equipment depends on the material on which the labelling will be applied.

Here are some key pointers you should be mindful of while using laser marking systems:

- Suitable safety goggles, depending on the laser’s wavelength

- Flame-resistant clothing

- Use lasers in a designated zone with visible warnings

- Keep in mind if the material will exude harmful fumes; build an infrastructure to contain the fumes

- Follow the operating procedures prescribed by the manufacturer and follow a regular maintenance cycle

- Never leave the laser unattended

The marking process, being paperless and chemical-free, is considered environmentally sustainable.

If the safety measures listed above are followed, the chemical-free process can reduce workplace hazards caused by abrasives.