Platform Architecture

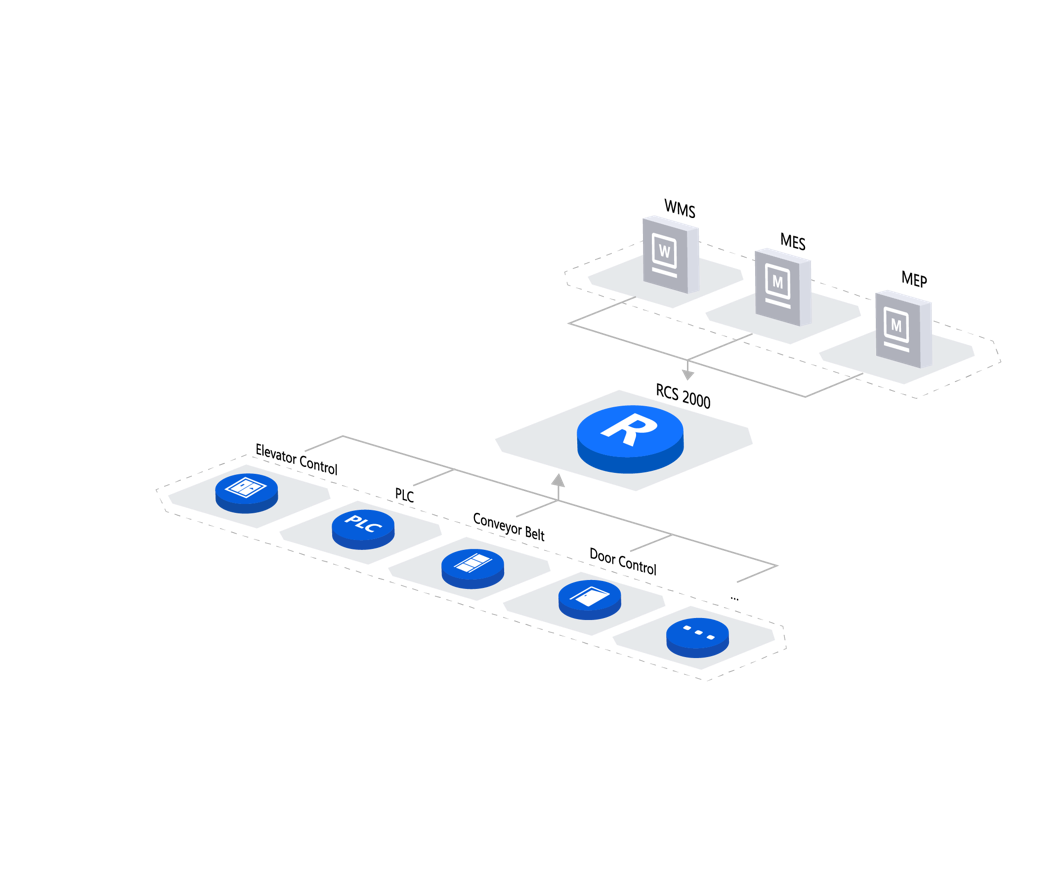

The core of Hikrobot software platform architecture is the iWMS 1000 (Intelligent Warehouse Management System) and the RCS 2000 (Robotic Control System). iWMS 1000 docks with the upper-level system seamlessly to realize intelligent warehouse management at high efficiency and low costs. RCS 2000 is used to build the map model and dispatch various robots. The two systems work together to link through the whole logistics process, connect various transfer scenarios seamlessly.

The core of Hikrobot software platform architecture is the iWMS 1000 (Intelligent Warehouse Management System) and the RCS 2000 (Robotic Control System). iWMS 1000 docks with the upper-level system seamlessly to realize intelligent warehouse management at high efficiency and low costs. RCS 2000 is used to build the map model and dispatch various robots. The two systems work together to link through the whole logistics process, connect various transfer scenarios seamlessly

iWMS-1000 (intelligent Warehouse Management System)

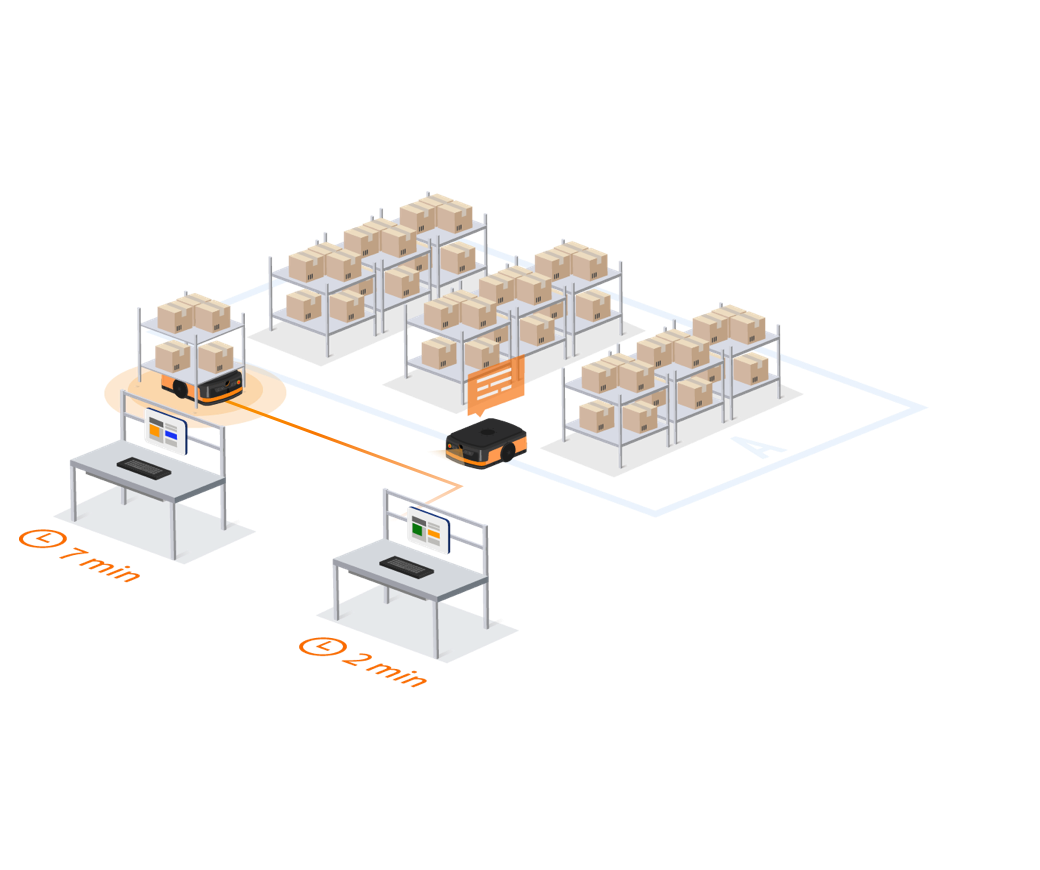

Taking Goods-to-Person as the core concept, iWMS can schedule the whole range of mobile robots via RCS, and dock with the ERP/MES/OMS system, providing an integrated solution for warehousing logistics.

-

Storage Location Recommendation

-

Storage Allocate

-

Smart Batching

-

SKU Velocity Management

Multi storage type-Single system

To achieve efficient operation, warehouses different industries set the warehouse layout according to corresponding business needs, such as High-bay rack area,Manual storage area, LMR storage area, CTU storage area, etc. iWMS-1000 supports multi – type storage zone management to realize overall management and reduce operation costs.

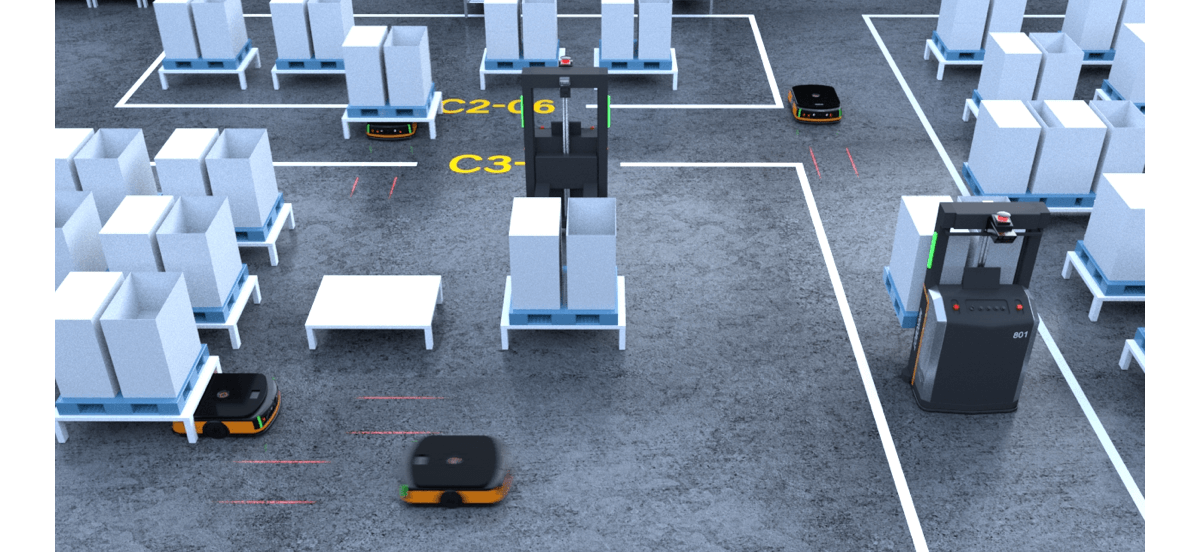

RCS is responsible for task scheduling, robot dispatching, operation and maintenance management. Based on various scheduling algorithms, RCS can realize optimal task allocation, multi-robots path planning, traffic management, etc. Scheduling multiple types of robots to work together, maximize efficiency is achievable in different scenarios.

Multi-types of Robots Dispatching

RCS supports controlling various types of robots, even making them share the same route. It delivers seamless transferring of warehouse-to-production and in-warehouse, etc. iWMS1000 works with RCS-2000 to realize cluster scheduling of hundreds of mobile robots and complete all kinds of G2P tasks.

AI-based Dispatching

Through data mining, the system can analyze and predict the time of task generation, schedule idle mobile robot to wait at the task point in advance, and improve the overall logistics efficiency.

According to the history data analysis, the system can estimate the picking time at the work station, and then adjust the queue strategy and shorten the task waiting time.

The system can assess the route congestion and workstation status, control the handling order, and achieve task load balancing.

High Flexibility and Compatibility

RCS-2000 can dock with WMS, MES,ERP, etc. For different scenarios, it provides standard interfaces for warehousing and transferring modes with high compatibility and scalability. It supports docking with automatic door, PLC, elevator, door control, conveyor and other external equipment, to meet individual operation requirements.

Statistics Display

Comprehensive performance data dashboard, includes task statistics, battery statistics, alarm statistics, etc. It helps operators get the real-time data and plan better.