What is a Static DWS System? How Does It Work?

A Static Dimensioning, Weighing, and Scanning (DWS) System is a standalone solution that enables automated volumetric-weight-based billing across industries. A key Warehouse Automation solution, Static DWS Systems primarily uses three distinct tools, which work in tandem to execute instant dimensioning, weighing, and label reading:

- 3D Profilers/Dimensioners for Image-Based L x B x H Measurements of Shipments, No Matter Their Shape (Cuboidal, Non-Cuboidal, Irregular-Shaped)

- Machine Vision-Enabled Scanners, which Read/ Auto-Identify Shipment Labels

- Load Cells that Register Shipment’s Dead Weight

When Should You Choose Static DWS for IntraLogistics?

Optimise Premium Warehouse Square Footage with All-in-One, Cost-Efficient Setup—

Built for Operations Fighting Space Crunch!

High-precision Static DWS Systems are designed in a relatively compact form factor that doesn’t feature an outbound conveyor, sending shipments to a sorter/ sortation system.

Automate dimensioning, weighing, and shipment label scanning—without the expensive real estate expansion a Dynamic DWS System will otherwise demand of warehouses with limited floor area!

Static DWS System | Dynamic DWS System |

|---|---|

| Compact | Space-Consuming |

| Cost-Effective | Relatively more expensive |

| No integrated with sorters | Integrated with sorters |

| Suffices for standard throughput | Relatively higher throughput |

Advantages & Workflow: The Complete Picture of IntraLogistics Automation with Static DWS

Why Are High-Precision Static DWS Systems More Cost-Efficient Than Dynamic DWS Systems?

If the operational space is limited, Static DWS for warehouses, dark stores, 3PL warehouses, etc., helps maximise ROI in the following ways:

- Save more on installation, integration, and maintenance expenses

- Invest the balance in other warehouse automation opportunities to optimise throughput

These pointers are relevant in the context of Static DWS for 3PL companies and Static DWS for Manufacturing.

What Are the Complementary Warehouse Automation Solutions That Optimise Intralogistics Automation with Static DWS Systems?

Pair high-precision Static DWS for warehouses, dark stores, and manufacturing units with mobile robots, AGCs, AGVs, and different AMRs, including Autonomous Forklifts for efficient Goods-to-Person and automated workstation-to-workstation material handling.

How to Create an Integrated Automatic Material Handling System with Static DWS, Warehouse Robots, Sortation System Conveyor, and Other Solutions?

Step 1: Leverage a host of autonomous and guided robots, including AMRs, AGVs, ACGs, for their specialised capabilities to load and unload shipments—cartons, pallets, totes—onto and off the High-precision Static DWS Systems.

Step 2: Command some of the robots in your Warehouse Robot fleet to carry shipments to the sorting station or other zones, such as the storage area.

Step 3: Unload the material for further handling by the ASRS System or load the shipments for sorting on the inbound feed of the sortation system.

What is the Software Interface of Intralogistics Automation with Static DWS for Warehouses and Other Similar Operations?

Operate different solutions, such as the Static DWS, AMRs, Autonomous Forklifts, and sorters, and gather the workflow data they collect or process via the interface of a robust duo of software platforms: Warehouse Management System (WMS) and Warehouse Control System (WCS).

Build a unified intelligence of enterprise data for smart decision-making!

to know more about Static DWS for Manufacturing Companies now!

Static DWS for Parcel & Freight: What are the Different Configurations of Static DWS Machines?

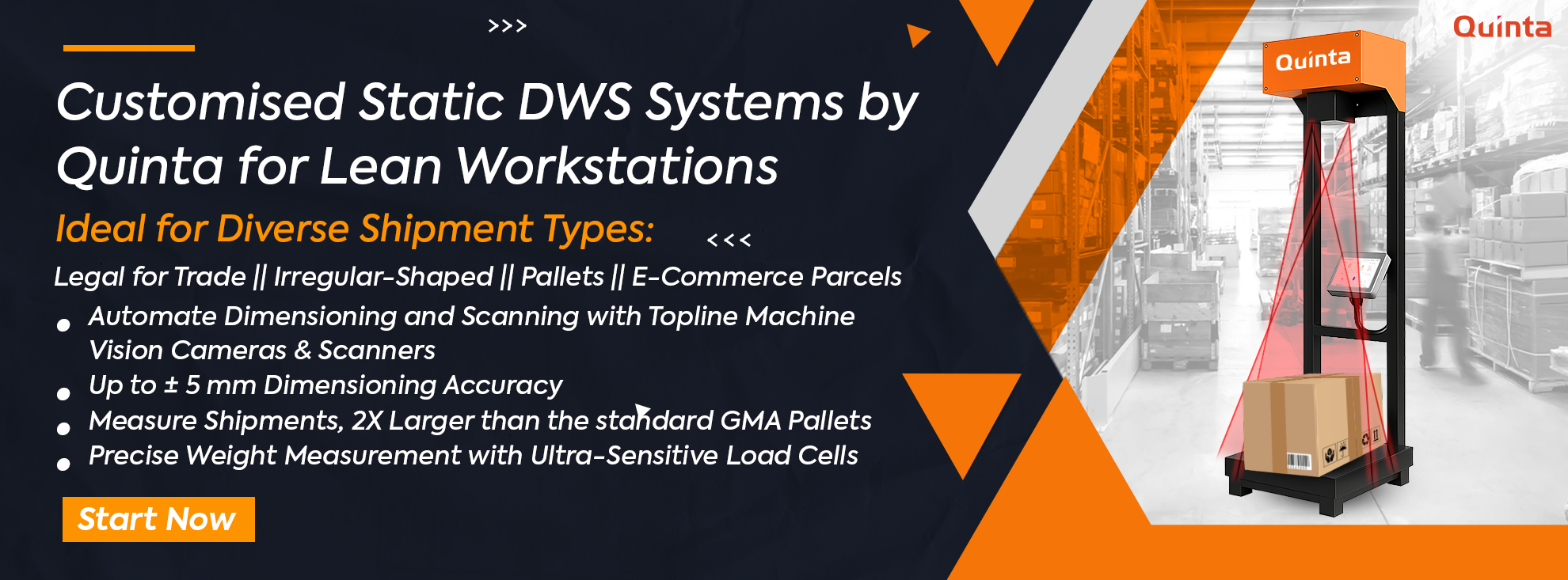

Lean Static DWS stations are customised for parcel dimensioning according to the use cases and the degree of automation for which the client opts. However, the constricted space of a DWS workstation may not suffice for large freight.

In such cases, a 3D profiler and a barcode scanner are fixed at a height. When vehicles with scale-integrated forklifts pass under the setup, the DWS System automatically capture the dimensional weight and the label-encoded details of freight.

Why Opt for Quinta’s Solutions?

Key Features of Quinta’s Static DWS for Warehouses

Accurate Dimensioning—the key part of the Volumetric Weight-Based Billing puzzle

Use powerful, Machine Vision-enabled line scanner 3D profilers to accurately determine the L x B x H, i.e., the volume of the shipments to the magnitude of a few millimetres.

Effortless plan logistics—freight and cargo boxes—and allocate last-mile or transit vehicles, for multi-modal routes.

Precise Weighing— instantly calculate the exact shipment load.

Tally customer-declared weight and optimise billing with cutting-edge ultra-sensitive load cells.

Foster better trust in your services, with transparent volumetric weight calculations that ensure the best rate in the market—eliminate unintentional overcharging, chargeback disputes, and revenue leakage due to undercharging.

Machine Vision-Powered Label Scanning—the most crucial component for inventory control and sorting

Identify even damaged, blurred, or low-contrast labels with high-contrast Machine Vision Cameras, integrated by Quinta’s experts.

Read barcodes, QR codes, and laser-embossed codes against different surfaces, without compromising throughput due to no-reads.

Thorough Integration into the Warehouse Automation Solutions Suite— ensuring workflow continuity by crunching the data captured by the Static DWS for warehouses

To scale up and to adapt seamlessly, centralise warehouse intelligence with uninterrupted data flow by integrating the components of the DWS solution into the WMS.

The WMS, in turn linked to the WCS, creates a robust enterprise data repository, while WCS controls and interfaces communication among the Warehouse Robotics fleet, the sorter, and the Static DWS.

Building the Perfect Static DWS for Unique Business Needs & Workflows—

Salient Points About Quinta’s Design Thinking Approach

Consulting for Gap Analysis and Project Planning

Whether it is Intralogistics Automation with Static DWS Solutions or a Warehouse Robotics ecosystem, Digital Transformation demands massive investment.

Hence, Quinta’s work begins with Gap Analysis, aligning the project blueprint with your business goals and the latest industry best practices, as well as documenting measures to future-proof your warehouse and logistics automation infrastructure—all chalked out within your budget!

Customisation

With Quinta, go beyond the constraints of one-size-fits-all solutions that force you to slow down or overspend.

Our experts take a Design-first approach to building Static DWS Solutions for warehouses. We specialise in building bespoke Static DWS Systems with:

● Different levels of Machine Vision capabilities and configurations

● Form factor of the load cell base, depending on the overall layout of your warehouse, your Warehouse Automation budget, and throughput goals.

Durability

We deliver solutions built with components engineered for harsh and high-volume industrial settings to deliver reliable performance with low maintenance cost and minimal downtime.

Hardware-Software Integration

Our technology experts bring a wealth of experience to the table, thanks to our collaboration with players across industries, particularly in the Warehousing and 3PL sectors, on their Digital Transformation projects.

A key expert-driven service we offer includes WMS and WCS integration with every solution we customise for you in your Warehouse Automation suite. This comprehensive hardware-software integration is the bedrock of automated decision-making across operations.

Industries Quinta’s Static DWS Systems Serve

- Third-Party Logistics (3PL)

- E-Commerce Warehouses and Other Warehouses

- Manufacturing

Impact of High-Precision Static DWS Systems on the Outcome of IntraLogistics Automation

- Optimal Throughput: Realised by the collective synchronisation of the customised Static DWS for the warehouse, the robot fleets, the sorters, and other automation solutions in the operations

- Accurate Billing: Enabled by precision measurements taken by the different Static DWS components

- Improved Transparency: Ensured by exact measurements, which translate into industry-best rates

- Better Control Over Process: Driven by seamless integration that empowers decision-makers to monitor workflow, intervene during a malfunction, and adapt to changes in process or warehouse environment in real-time

Specifications of the Quinta Static DWS Systems

- L x B x H—Max 1200 x 1000 x 1000; Min 100 x 100 x 100

- Weight—Max 80 kg; Min 500 g

- Types of Packages—Flyers, Carton Boxes, Shrink-Wrapped Boxes, Poly-Wrapped Boxes, and Non-cuboidal Shipments (Even Irregular-Shaped Items)

for Static DWS for 3PL Companies now!

Frequently Asked Question

Static DWS for warehouses helps improve:

- Billing accuracy (avoids revenue loss)

- Operational speed (fewer manual processes)

- Error reduction (fewer returns and misroutes)

This leads to significant cost savings and better ROI.

Yes, Quinta strives to ensure effortless IntraLogistics Automation with Static DWS for warehouses, thanks to WMS/ERPs with easy API-based (plug-and-play) integration.

Quinta strives to offer DWS installation as well as hardware designs that specifically address the challenges and goals of our clients. Hence, we don’t have one-size-fits-all pricing for installation and hardware-software integration. However, we remain committed to offering resilient, accurate, and cost-effective automation solutions for our clients, who have often reported high ROI on their Digital Transformation projects.

Quintas Static DWS for warehouses and 3PL companies need minimal maintenance if checked regularly for the following:

- Cleanliness and calibration of sensors, scales, and other equipment

- Software updates

We also offer extensive and quick-response post-sale customer support services, including remote diagnostics and on-site maintenance.